The present video was recorded in May of 1992 and contains an interview with Stan Meyer in which he candidly discusses the various components of his water-powered dune buggy.

In the first portion of the video, Meyer discusses his purported water splitting technology as implemented in the vehicle. In the second part, he talks about his religious inspirations.

I have transcribed the video below.

—

[02:16] (To the cameraman) Can you zoom in back in here?

[02:24] Are we on?

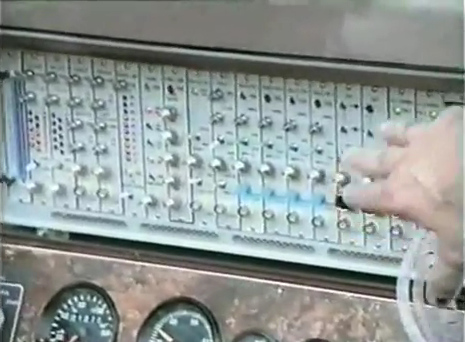

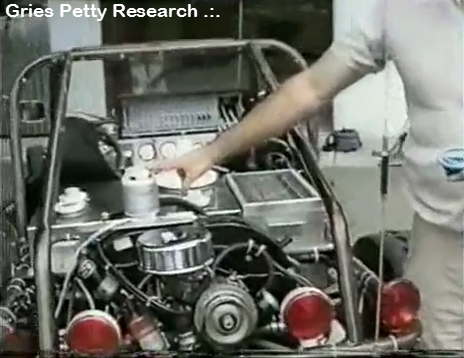

[02:25] Ok, now this is the Hydrogen Computer System which was designed in order to be able to process the fuel to produce the hydrogen gas from water and do it economically and be able to control its firing allowing the Volkswagen engine to run off of hydrogen. There’s a lot of engineering design that went into this even though this is our systems engineering approach. The Hydrogen Computer System you see here will be miniaturized down to several IC chips which will allow us to give the economics to apply to a conventional car.

Figure 1. – Hydrogen computer system aka. the GMS

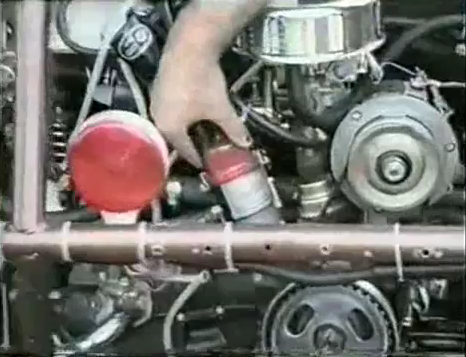

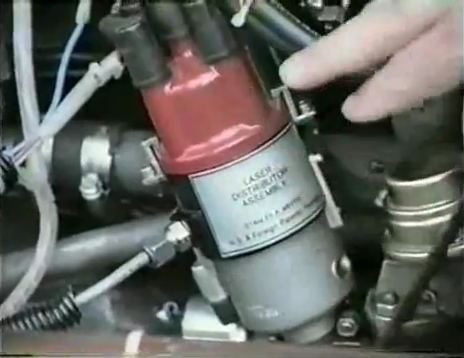

[03:08] Over here there are very unique design features that had to be developed in order to develop the water fuel cell as a retrofit energy systems to conventional cars. We had to go ahead and develop what we call the laser distributor as you see right here,

Figure 2. – Laser distributor system

Figure 3. – Laser distributor system, closer view

[03:25] which is put between a conventional rotor cap and that of the rotor assembly. And primarily what this does is this sets up the electronic signals that go back and triggers the computer system (Meyer points at the GMS) in order to allow the car to run successfully on hydrogen.

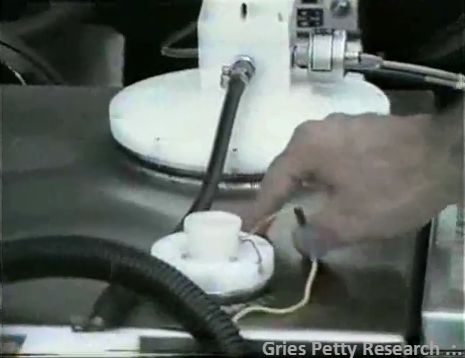

[03:42] In order to run this engine off of water, we’ve also had to learn the ability to adjust the burn rate of hydrogen to co-equal the fossil fuels. We did this by simply now pulling off a portion of the exhaust gases as you can see through this tube here

Figure 4. – Electronic meter mixing the exhaust gases

[03:59] going to this electronic regulator that’s hooked up to the hydrogen computer. And basically, what’s happening is that the ambient air is going into the engine and going through the burning process it produces the non-combustible gases that retard the speed by which the oxygen atom unites to hydrogen to bring on gas ignition. So by simply using the non-combustible gases coming from the exhaust of the engine, we now modulate and control the speed by which that oxygen unites with the hydrogen and therefore we are adjusting the burn rate of hydrogen to co-equal that of gasoline or fossil fuels or even diesel fuel. And that gave us the number one retrofit capabilities of retrofitting the water fuel cell technology to an existing engine and we do this electronically.

Figure 5. – Gas processor unit

[04:46] The unit that you see right here, we call this a gas processor. And basically, what we are doing is we are ionizing the ambient air gases that are now going into the process and this allows us to trigger and use the hydrogen fracturing technology and tapping into a higher energy yield coming from the hydrogen.

Figure 6. – Resonant cavity unit

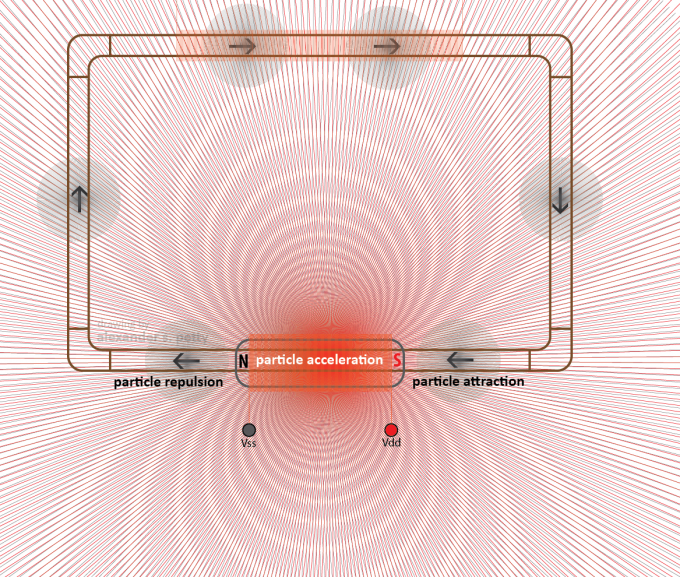

[05:05] The unit that you see right here (see figure 6), this is referred to as the resonant cavity.

Figure 7. – Water tank that feeds the resonant cavity unit

[05:10] Water is now fed into the resonant cavity through this water tank (see figure 7) and as such we now expose the water to a very high intense pulse voltage field and restrict the amps and therefore the electrical polarization process now allows us to release the hydrogen economically from water. And by attenuating the amplitude of the voltage field, we now can control the rate of the production of the hydrogen gas on demand. So this is what’s referred to as a constant demand generator. We also now extend or allow the voltage amplitude to increase even to a higher level and allow the water atoms to go into an ionization state which gives us an ability even to produce a higher energy yield by producing more hydrogen gas on demand.

[05:58] So the fuel now, coming from the water through the electrical polarization process going into resonance, resonance meaning that we are actually tuning into the dielectric properties of water. And allows us to reduce amp flow down to a minimum and allows voltage to take over to disassociate the water molecule on demand.

Figure 8. – Electronic Injector system regulator unit that meter mixes combustible and non-combustible gases to provide burn rate control

[06:16] And those fuel gases are now coming through this electronic injector system as you see here. So basically, we are now feeding the ionized air from the gas processor. We are now also taking the water fuel gases that are now coming from ordinary water. We are now mixing it with non-combustible gases, the ambient air gases, and regulating this control of the fluid medium and as a result, now we can tune in and allow this engine to run off of natural water.

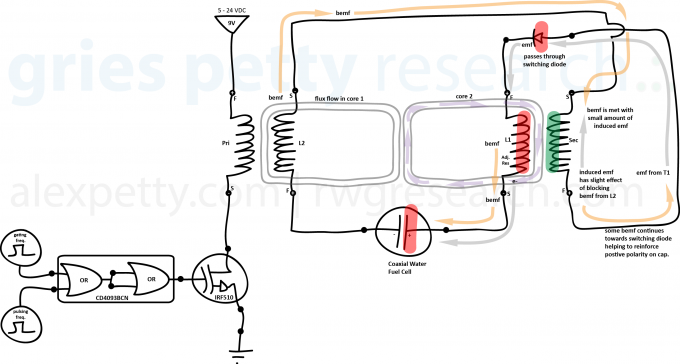

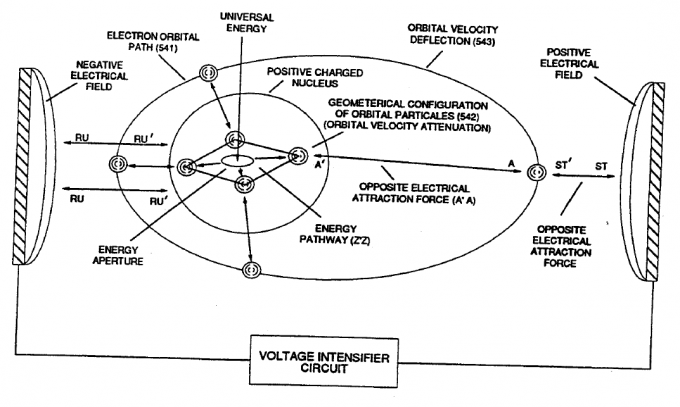

Figure 9. – Voltage Intensifier Circuit (VIC) unit

[06:50] This systems approach, this particular unit here (see Figure 9) is referred to as the VIC or the Voltage Intensified Circuit technology. This is being miniaturized down to a very small lightweight system. This is demonstrating our systems engineering approach on a technology that we can apply it to other applications not only in transportation but also in the industrial applications. So it was paramount that we would demonstrate and have the technologies solve for design engineering retrofitting to existing energy consuming devices whether it was running an internal combustion engine or a diesel engine or hook it to an industrial process. So all of these design interfacing technologies are now being solved. We are now in the latter stages of what we call the pre-engineering system which will now allow us to miniaturize the technology. Once we are completed on the design applications, we can take it into mass production.

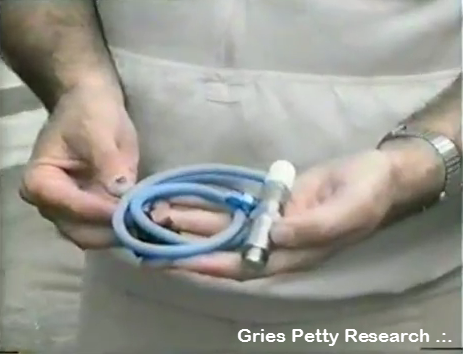

[07:48] I’ll give you a classical example of this, we’ve also developed from this technology which we’ve called the water fuel cell injector

Figure 10. – Water-fuel injector

[07:57] and basically this injector now is a miniaturized water fuel cell or miniaturized resonant cavity. And this technology now allows us to simply replace – we can bypass this part of the system’s approach and now simply replace the spark plug with the water fuel cell injector

Figure 11. – Water-fuel injector installation point

[08:18] and as a result now we can run water up to the injector which is now being processed and being exposed to a very high pulse voltage frequency and as a result as the water fuel is going into the system then the explosion takes place inside the cylinder therefore makes this an extremely fail-safe operable system.

[08:39] The cord that you see here is strictly hooks up to a very high-intensity voltage pulse and we restrict the amps to cause the electrical polarization process which in turn turns the voltage amplitude now takes it and goes in the ionization state and performs the hydrogen fracturing technology and then, in turn, the high pulse voltage frequency now allows the ignition of the gases. So, therefore, we do this electronically and so this technology is taken us down to the water fuel injector as you see here today which gives us a very economical way of simply converting and running a conventional car on ordinary natural water.

[09:24] So basically, what we do is we feed ordinary, natural water in here; non-processed natural water, we now feed the ambient air gases, being ionized, it’s being mixed with the water, and then we mix the non combustible gases going into the system that regulates the control that allows us now to release the thermal explosive energy from hydrogen and do it on a controlled means.

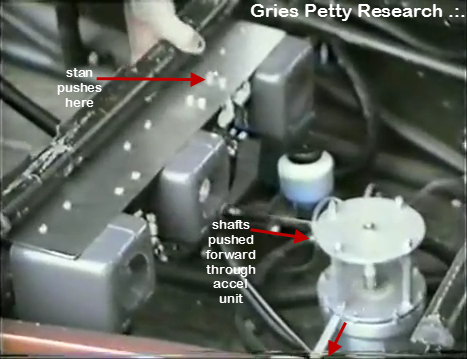

Figure 12. – Laser accelerator control unit

Figure 12.5 – Laser accelerator control unit, close up

[09:56] Further development on the technology centered around also the development, what we call the laser accelerator control (see figures 12 and 12.5). And this had to be developed in order to translate from a mechanical displacement to an electronic displacement in order to allow the hydrogen computer system to produce the gas on demand based on acceleration control. So what you are really seeing with the water fuel cell as it is today is that we have a full system engineering approach allowing us now to use water as a main fuel source to able to run a conventional engine and run it on water and do it in equal or supersede the performance of a car running on gasoline or diesel fuel.

[10:44] Many people do not realize that when you run a car or truck on gasoline or diesel fuel, you are actually running it on hydrogen. And all we are doing is using the hydrogen from water. And under the National Bureau of Standards figures shows that when you use water, the energy release is roughly two and a half times more powerful than that of gasoline. So water is a very powerful fuel. And all you needed to do was solve the answers; number one producing the hydrogen economically, controlling it on demand, being able to adjust the burn rate of the hydrogen gas to co-equal the fossil fuels and the third one was to be able to transport it without spark ignition. And we’ve solved all of these problems on the design engineering, and of course the water fuel injector as I’ve shown you, now gives us the abilities to transport the water directly to the fuel injector which is now going into the voltage zone which is now performing the electrical polarization process that goes and triggers the hydrogen fracturing technology. But it’s doing it inside the engine. So we all know that natural water is very stable and therefore it becomes a very fail-safe operable system as we pointed out earlier.

[11:58] (Meyer’s assistant) And do you want to say something about how we constrict amp flow?

[12:02] Yeah, we talked about that.

[12:02] (Meyer’s assistant) Did you mention something about that?

[12:03] Yeah. So in a system engineering approach, in mass production, it looks like we can translate and reduce the systems approach down to a unit that costs roughly 1500 dollars per vehicle. For trucks, it will be slightly larger than that, below 5000 dollars – it looks like we will be able to reach the economics to it and using ordinary natural water. You add nothing to the water, you don’t process the water in any way.

Figure 13 – Steam resonator unit

[12:32] Now here is another feature to the system that everybody asks me about (See figure 13). They say, “What happens to the water in the winter time? Does it freeze up?”. Well, part of our technology was in the areas of development of what we call the steam resonator. Now since the unlike atoms take on opposite electrical charges, we simply use another part of our technology to restrict the amps and let voltage to take over and therefore we agitate the water molecules which in turn generates kinetic energy which in turn heats the water. Now, this is phenomenal in the fact that we consume very little electrical energy in order to heat the water. So there are very far-ranging advantages and features to this technology, arranging even in the areas that we now have a way of using voltage by switching off amp flow and dealing with the environmental control areas we are developing the technology in the areas of desalination of salt water. Whenever you have a free or abundant energy source like water, it’s only limited to the imagination to put it to work. This technology is very applicable to desalination of the salt water, the handling of toxic waste chemicals by high pulse voltage frequency and restrict the amps, we now can separate the molecular structure of toxic chemicals and render them useless and safe.

[13:49] It also takes us to the technology of combining, unlike atoms that heretofore was not possible under the natural state of covalent link-up. This led us to the development of the EPG electrical generator technology where we are able to manufacture a magnetized gas that exists at room temperature and enhance the electromagnetic field without increasing mass. So our technology since the time of the Arab embargo has been very far-reaching to give us a comprehensive energy source that would literally be used anywhere in the economies and do a bi-lateral movement throughout the economies of the world to bring an energy source in. And as I pointed out earlier, the pinion of energy prices that will confront us very quickly, we literally have the ability now of engineering systems that systems engineering mass production systems very very quickly. And hopefully, be able to stem off the imminent energy crisis that is now occurring. A lot of people are not aware of that Kuwait produces or manufactures the majority of aviation fuel for the world and its anticipated, as pointed out earlier, that its possible that as much as 20% drop in aviation fuel may occur within 6 to 8 months. If that happens then the dominos effect will occur and will start to trigger an energy shortage throughout the world.

[15:10] The same conditions that happened in the United States are also happening in the Arab fields where the natural pressure in the existing oik fields are dropping. The only difference between the U.S. and the Arab fields is their pressure is dropping 3 times faster than occurred in the United States. You just can’t keep pulling the oil out of the ground and expect that it’s going to be there forever. The hourglass effect is occurring at a more faster rate than now in nuclear power plants. China has opened the doors to Western technology, 25% of the population of the world wants the same goods and services that you and I have been enjoying and that industrial base cannot be maintained or expanded without the supply and utilization of energy of which we have very little fossil fuel left. So it’s imperative that we developed a technology that we can move very quickly and of course, water was the answer to it – because water is a very free and abundant energy source. And so this technology has led us to the abilities of harnessing and using the water in this particular way which we call the water fuel cell technology.

[16:12] (Interviewer) Do you have an indication of the amount of energy stored in a gallon of water compared to a barrel of oil for instance?

[16:21] Yes. As I pointed out earlier, when you separate the hydrogen and oxygen gases and go into the gas ignition process, its energy releases roughly two and a half times that of gasoline. Now note the reference is not two and a half times that of fingernail polish, its two and a half times that of gasoline.

[16:39] But in the hydrogen fracturing technology, we have developed a technology – as the Lord has shown me – that by igniting the hydrogen and oxygen gases, and setting up a condition by which the water molecule is prevented to form, then we now can tap into a very higher energy yield, and as a result of this, the hydrogen fracturing technology shows that we can release energy up to and beyond 2.5 million barrels of oil per gallon of water and do it safely.

[17:07] And as I showed you earlier, we are now preparing this technology to be retrofitted directly to a jet commander which we plan not only to fly around the world non-stop around the equator but turn 90 degrees and go from the north and south pole. So its a tremendous amount of energy source. And what we have done is found a triggering process to allow us to release a tremendous amount of energy and do it safely. So it gives us an ability to not only sustain and maintain the economies of the world but also give us the abilities to handle the environmental pollution problems at the same time.

[17:42] We can’t keep putting CO2 in the air and expect that the energy levels are going to be there even for our plants. And we all talk about the Greenhouse Effect but very few people come up with a viable answer to it. And the water fuel cell technology gives us the ability.

Figure 14. – Stan Meyer and looking at his work

[17:57] (Interviewer) Stanley can you explain your driving force behind spending all this money and energy developing something like this. It’s cost you about ten years of your life. Can you explain why you are doing all this and what really drives you to keep going?

[18:14] Well I did an analysis during the Arab embargo as to what actually occurred, and I realized that without a new and abundant energy source that was to come into the world economy very quickly, then the world economy could collapse. So as a scientist, I have a very diversified background, from research development to product development engineering and corporate entrepreneuring. And when I realized the problem that was confronting us, I went into my office laboratory and as a scientist, I had always believed in the existence of God. I thought it was mathematically impossible that we had derived ourselves from swamp gas. If you have to have a lot of faith to believe in evolution. And so I went into my office laboratory and I said, “God, I love my country. It’s the greatest country in the world. If you’ll help me put a power supply in the country I’ll do anything that you want me to do.” And subsequently, I was like Paul on the road to Damascus. I didn’t know the Lord, but once he revealed himself to me, subsequently I was filled with the Holy Spirit and I have been exercising the power, the authority and the word of God bringing this technology in. And many people ask me about do I fear for my life, I have learned the power of angels and I have been protected in trying to bring this technology in.

[19:28] The ultimate objective is not only to stabilize the economies of the world but if we realize any funds from the technology it will go into world evangelization. You see, as a scientist, once truth is shown to me, truth is truth, of course, I got what I wanted – a ticket to going to heaven – and I got filled with the Holy Spirit, and so as a scientist, truth is truth and I have a responsibility just as I have a responsibility to the water fuel cell technology, to try to bring it out in the world, I also have the responsibility really to take the word and the truth of God, not only to the guy who next door neighbor, or the guy down the block, but also relate that truth of that knowledge to every person in the world if I possibly can do it. So the ultimate objective of the water fuel cell technology really is to help set the financial base capable of evangelizing the world.

[20:19] Now there is a difference between spiritual knowledge and worldly knowledge. And you can’t go to the world system and ask them to help evangelize the world and spread the gospel but you can go to the world’s system and give them a cheap power supply that’s so economically and then those funds will go into the world evangelization. So the water fuel cell technology really, the ultimate objective is to accomplish the task of evangelizing the world by giving the financial abilities to do so. And that’s my ultimate and prime objective. The water fuel cell will give us the abilities to do this.

[20:55] (Interviewer) Can you explain – you mentioned one Bible text – what do you mean by that?

Figure 15. – Stan Meyer’s logo

[21:03] Well, you notice on my logo, you’ll see Job 38 verse 22 and 23 and this is where the Lord is talking to Job and he asks Job this question, he says, “Have you considered the treasures of snow? Or have you considered the treasures of hell which I have reserved against the time of trouble against battle and war.” The interpretation of the scriptures is as follows. Is not snow the most beautiful part about water? That no one snowflake looks exactly the same as that of another. The treasures of snow are the characteristic knowledge of water. The Lord knew that in fact that we would have and reach a very critical point in our history that since we went on our path that we reach a limit in the flow of fossil fuels and that the flow of fossil fuels may be disrupted and as a result the lord specified that the knowledge of water would come at a time of great trouble. But he also specified that the knowledge would come out prior to two events.

[the film was edited and a portion of the interview is missing]

[21:56] (Interviewer) Now that we’ve heard how the thing functions, and you’ve explained background – why you are working on this thing – what do you think are possible applications and where do you think this device can be applied and what scale? What is the amount of energy we can get out of it? You talked before about converting cars, commercial airplanes. Is there any other application you can think of?

[22:20] Oh yes! Not only is this technology applicable to all modes of transportation but it also has application in industrial processes. During the Arab embargo, I was called into a meeting in Columbus, Ohio with the industrial leaders and the Columbia Gas system informed us that our gas was being cut off 100%. What they actually were telling us is that we were going out of business. And I saw some of the richest and most powerful industrial leaders of the state popping pills and I thought they were going to have a heart attacks because basically without energy you can’t make a product, and you can’t make a product you can’t make profit, and if you can’t make a profit you can not pay your bills. The result is that the bigger you are, the faster you would go into economic bankruptcy. So, it was imperative that this technology not only is developed for the transportation areas but also to applied to industrial applications to be able to give energy.

[23:12] The technology in the hydrogen fracturing technology gave us the abilities to go in and protect the military integrity of the western world. So this technology is applicable not only in those areas but – for an example, during the Arab embargo, our Navy task force did not have the fuel and so as we have the ability now to go into maritime applications and literally run the ships off of water as the main fuel source and at the using the application is cleaning up our environment and preventing from the COT and the catastrophe contaminants that go in the air.

[23:45] So, we can move this technology bi-lateral in every aspect of the economy and do it very, very quickly. And so that leads us now into the fact that we have been developing this technology for mass production. And so, once we finalize the debugging of the pre-engineering unit, then we are going to translate it into a very cost-effective system by taking the technology in the microchip technology and plastic mold injection technology allows us now to move this type of technology very very quickly. As a matter of fact, one master mold can produce over 11,000 units every 24 hours. That gives us the abilities now to move in a bilateral movement to get the energy source throughout the entire world quickly if the oil is shut off to us either by way or by some other methods. A lot of people do not realize Saddam has the bio-germ through genetic restructuring. That if he uses it, it lives off the bacteria of air and water and even of oil. If he uses this its possible that the oil could be contaminated very quickly and if that is so then every country in the world would be faced with shutting off the flow of oil to each of there countries. Now without the supply of fossil fuel, within 180 to 240 days thereafter, about 1.5 billion people would be facing starvation very, very quickly because we need that flow of energy in order to maintain the industrial bases of the world.

[25:15] So, we’ve designed a technology to be very flexible, to be used in every segment of the economy and do it very quickly. So we are all in the same boat and what we are doing is illustrating that yes, the technology is viable, here we do have a viable technology that we now can use water as a fuel source because water is a very free and abundant fuel source. But it’s going to take you and I and the guy down the street and the people in each country to bring this technology into the marketplace to stabilize their countries. And so as a result, we developed it under the KISS method, “Keep It Simple Stupid”, to comply with the law of economics, that the guy who comes up with the cheapest way is going to win out. So by decentralizing the mass production of this system and the fabrication of the system, and decentralize the installation of the system, then we should be able to move in a bi-lateral movement throughout all the countries of the world to get this type of technology into their countries to stabilize their economic base. If the oil is cut off by these means or is simply being cut off by a lack of oil that is now showing. It’s the same natural pressure that dropped in the Arab fields as I pointed out a little earlier is also occurring in the North Sea. The North Sea pressure has dropped by one third. So we all need the energy and therefore I feel that it’s going to take the people of the world to come together, and the leaders of each country to come together in one accord in order to allow this type of technology to go into the stabilized economic basis in each respective country.

[26:46] (Interviewer) Do you have any time scale for mass production set up yet? And second, do you have any organization or are you planning an organization, international or..?

[26:56] Yes, I am negotiating with many leaders in different countries of the world. But the ultimate objective is to mobilize the masses of the people in order to bring it in. This is the only way that it can come in. And so as we finalize a debugging of the system, and take it into mass production areas, we can do this by turning the technology over to many many fabricators and people who have certain skills in the machining areas or the mass production areas that will allow this type of technology to be produced very quickly.

[27:29] (Interviewer) Thanks very much for this interview.

[27:31] My pleasure.

[27:33] (Interviewer) We appreciate it very much, thank you.

[27:34] Your welcome.

[the film was edited and loops back to a different point in the tape]

[27:45] (Interviewer) Stanley, can you give us some idea about the size of a conversion kit for a car for instance? We see all of these electronics sitting there (the interviewer points to the dune buggy)

Figure 16. – Stan Meyer’s dune buggy and its many electronics

[27:53] (Interviewer continues) but I guess this is not going to be part of a future upgrade kit for a car, is it?

[28:00] No. This is the pre-engineering unit in order to satisfy the U.S. code of operability on section 35 section 101, and it was developed as pre-engineering to show to the operability of all the different operational parameters of the water fuel cell. But in actuality, the entire technology that you see here is really reduced down to the water fuel cell injectors you see right here.

Figure 17. – Stan Meyer’s water fuel cell injector

[28:25] (Interviewer) This is the only thing needed in upgrading a car? Or is there anything else involved?

[28:29] No, the water fuel cell injector, which replaces the conventional spark plug in an internal combustion engine, this is hooked up to a water tank. Basically, if you have a plastic fuel tank in your car, you simply drain out the gasoline, flush it out, fill it up with fresh water. Then, the water fuel cell injector now allows the water to be transferred. The systems approach allows the water to go into the injector which is now being processed to release the thermal explosive energy from hydrogen.

[29:02] The second part is hooked up, again, is what we refer to as the gas processor.

Figure 18. – Gas processor unit

[29:07] that’s ionizing the gas to allow it to come in. So basically, in retrofit, all we are doing is simply tapping off the exhaust gases

Figure 19. – Tapping off of the exhaust gases

[29:13] from the conventional engine, we’re now using the gas processor to utilize the ambient air to ionize the gases which is now mixing with the water which now converts to water fuel. We are allowing the water fuel to go into the injector that’s now plugged into our replacement spark plug and allows the engine now to run off the thermo-explosive energy from hydrogen. So basically, all we are doing is taking the gasoline out of the tank, filling it up with water. We now replace the spark plugs with the water fuel cell injector, and we now hook a small little miniaturized computer which controls and meter mixes the gases going into the engine to allow the engine to accelerate and decelerate. So the installation is a very small, lightweight, compact electronic control system.

[30:05] (Interviewer) Ok, the distributor, is that going to be the same distributor? Or do you have a modified version? Or is there anything additional to it?

[30:11] Yes, we do modify the distributor as is shown over here

Figure 20. – Modifications to insert Meyer’s Laser Distributor between the distributor cap and distributor assembly

[30:17] We simply take off the conventional rotor cap off a conventional engine, and we put the laser distributor in between the distributor assembly and the cap and this (referring to the laser distributor) now sends signals to the computer system which will really be a composite of several integrated circuit chips that miniaturizes the hydrogen computer system.

[30:45] (Interviewer) This whole hydrogen stuff, isn’t it extremely explosive in the car? Is there any danger involved in the safety aspect of it all?

[30:51] No. We’ve actually solved the problem. There is no storage of hydrogen whatsoever. The water goes into the injector, which now allows it to go into a high pulse voltage zone, which performs electrical polarization process – so the water is only being converted into the thermal explosive energy as it enters the injector so the thermal explosive energy is now only occurring inside the engine. So the electronic system is designed to regulate and control the explosion of the energy so now it co-equals that of gasoline so there’s a tremendously fail-safe operable system.

[31:22] (Interviewer) Ok. So it’s safe, it’s a small system

[31:25] Yes.

[31:26] (Interviewer) What about the maintenance of the car engine itself? Do we need more maintenance? Is it different? Do we have to modify anything on the maintenance schedule?

[31:36] No. Just keep the same maintenance as you have it. Since your releasing thermal explosive energy into the engine and your co-equaling the burn rate of gasoline, there is very little maintenance. If there is any maintenance at all, we developed the technology years ago that we could really impregnate the cylindrical walls of the engine with Teflon and we can even impregnate treat the bearings and literally run an engine on off of the Teflon and eliminate the oil. If that occurs then, you can use a product something like Slick50 in the engine and if you would need it. But the wear factor, since its a very clean burning fuel, hydrogen is a very clean burning fuel, then the engine oil is not contaminated under the old method of running a gasoline engine or diesel fuel. So its an extremely clean-burning fuel.

[the film was edited and loops back to a different point in the tape]

[32:35] (Interviewer) Stanley, what about the valves in the engine? Don’t the piston’s burn out because there is no lubrication of the lead or any other additives to the usual gas engine?

[32:44] No. The valves have been designed very recently to operate off of non-leaded gasoline. And since we use the exhaust gases to cycle back in and to modulate the burn rate of hydrogen gas, as we now control the burn rate to co-equal gasoline engine temperature and operations are duplicating the same thing on gasoline or diesel fuels. So you don’t change the engine in any way. This allows us now to retrofit the water fuel cell technology to an existing engine. And that’s very important because it now gives us the ability that we can stabilize transportation as we talked about before if the energy is cut off.

[33:26] (Interviewer) Ok. Now the accelerator. Can I still keep the same mechanical accelerator? Or do you have a new device for that as well?

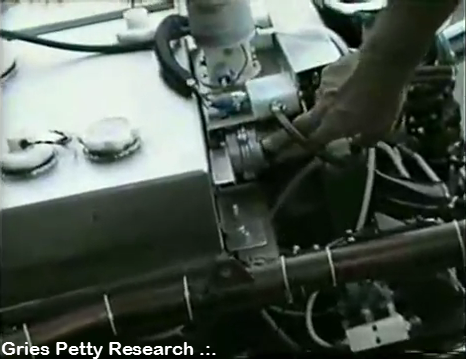

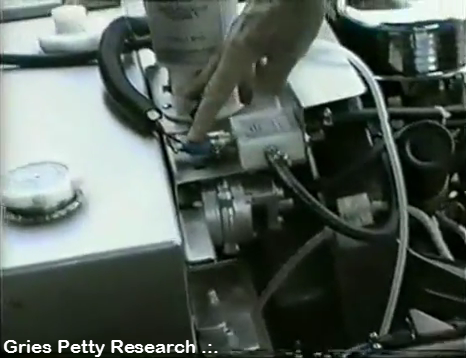

[33:31] Yes. We have developed what we call the laser accelerator as you see right here here

Figure 21. – Laser acceleration assembly

Figure 21.5 – Mechanics of the laser acceleration assembly

[33:45] that simply is attached to the accelerator pedal and as you press the gas pedal down, it displaces the mechanical displacement into electrical impulses which now is fed into the microminiaturized computer electronics. So, this gives us the abilities now to control the acceleration. This type of technology has given us the abilities to equal or supersede the performance of acceleration or deceleration of conventional cars running on gasoline or diesel fuel. So the hydrogen being two and half times more powerful then gasoline gives us a tremendous amount of performance over the prior state of the art.

[34:32] It runs very smoothly and it has a very unusual sensation. Generally, when you’re running a car on gasoline, you have this kind of a pause. But when you are running on hydrogen in the way that we’re doing it, its a tremendous, its a constant acceleration. So its an extremely very fast responding fuel source that’s coming from water, from hydrogen.

[34:55] (Interviewer) So your claiming that the performance is equal or better as a normal gasoline car.

[34:59] Oh yes. Definitely. It’ll even start up quicker. In the winter time, you are dealing with liquid gasoline or liquid diesel fuel and you have problems with starting. In cold weather, you don’t freeze gas atoms and so by converting the water into instant energy, it gives us the ability to start the engine very very quickly.

[35:23] (Interviewer) So when you start an engine in the morning for instance, how long does it take before you can drive away?

[35:30] Oh, it’s an instantaneous start-up. Immediately when the pulse voltage frequency hits the water, it converts it to the gas which now produces the thermal explosive energy so its an instantaneous type of start. The electronic circuit interfacing gives us the abilities to control and meter the amount of water that’s going in on the start condition as opposed on a run condition. So the computer automatically adjusts between the start condition and the run condition. So electronically we have the abilities to adjust for these parameters. And the same as a conventional car, we also have the abilities to adjust for different ambient air conditions going from sea level up into the mountain ranges so automatically the electronic circuitry design gives us the abilities to adjust each parameter and give us a very smooth operational performance.

[36:23] (Interviewer) What about air pressure? I mean when you go up high in the mountains you don’t reduce ambient air there is no improvement in the performance of the car.

[36:36] No, because here we have a device, a metal bellow, which now allows controlling the amount of ambient air going into the engine of the car.

Figure 22. – Metal bellows device allowing control over the amount of ambient air going into the engine

[36:51] this automatically allows us to regulate the ambient air pressures going from sea level up into the mountain areas. So electronically these solenoids you see here

Figure 23. – Solenoids with pressure sensors that allows the computer to perform air pressure compensation as needed

[37:02] have sensors that automatically senses the amount of ambient pressures and they are automatically electronically adjusted to compensate for the difference of air pressure. So this allows us now to give tremendous good performance going from sea level right on up into the higher mountain regions.

.:.

How far are we from being able to buy the spark plugs that can substitute gas with water?